Description

About the C-630

C-630 Commercial Water Distillers are in use around the world. From a bottled water operation in Kyushu, Japan, to soup manufacturing in Portugal, to drinking water for a 25 floor luxury high-rise in New Jersey, to a 1.4 million square feet distributor center of a major retailer in Southern California. Pure Water distillation equipment is long lasting and trusted the world over.

Rely on Pure Water Brand

Pure Water brand equipment has been operating in more than 100 countries globally for more than 35 years. From embassies, large oil companies, multinationals, international schools, hospitals to small systems designed for homes, Pure Water is a brand people have relied on. Installation and training offered world-wide and training programs are given several times a year in the U.S.A. for foreign visitors.

High Purity Steam-Distilled Water

In today’s insecure world the assurance that you will have high-purity water produced by a superior water purification process will give you peace of mind.

Specifications of the C-630 Commercial Distiller

Feed Water Requirements

- 35-85 psi (constant flow)

- 900-2500 gpd (depending on setup)

- Zero grain hardness

- Silica levels <10 ppm

- Chlorine-free

Construction Material

- 304 Stainless Steel

Electrical

- Voltage: 208V, 220V, 240V

- Min. Continuous Amps: 83, 79, 72

- Watts Usage: 14 KWH

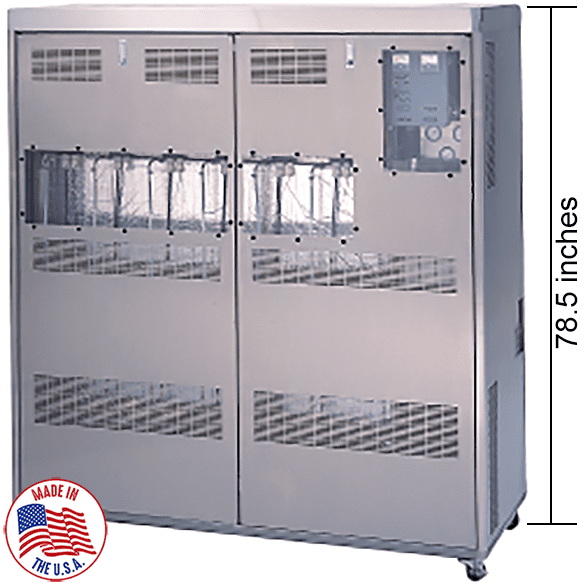

Dimensions

- Width: 72.5” (184.2 cm)

- Height: 78.5” (199.4 cm)

- Depth: 26.5” (67.3 cm)

Production

- 600-640 gallons per day

Shipping Weight

- Crated: 1350 lbs. (612.4 kg)

- Uncrated: 1250 lbs. (568 kg)

Portability

- Casters

- Can be lifted by forklift

Optional Enhancements

Pure & Secure can also provide all that Is required to make the C-630 Steam Distillation Unit into a complete system for your specific application. Typical enhancements include pre-treatment, storage, post-treatment, water distribution and dispensing.

Ideal for:

- Hospitals

- Commercial Buildings

- Schools

- Dental Clinics

- Pharmaceuticals

- Defense Contractors

- High Security Installations

- Aerospace

- Photo Processing

- Battery Maintenance

- Food Processing

- Cosmetics

- Sports Nutrition

Barrier Purification

Most water treatment is done by “barrier” processes. A barrier is placed in the water stream, and the barrier separates out contaminants and lets “treated water through”. In a barrier process, there is raw water on one side of the barrier and treated water on the other. Barriers deteriorate over time and the effectiveness drops.

In cases of severe contamination the barrier may be rendered useless because the contaminants have direct contact with the barrier.

Thermal Purification – Steam Distillation

Steam distillation lifts the water from impurities and does not rely on a barrier process. Instead, it is based on the Physical Laws of Nature. Just as the Hydrologic Cycle transforms sea-water to fresh water in a thermal cycle, so does the steam distillation process. It’s as simple as 1-2-3 and works independently of any barrier – just ask the people of Hawaii who rely on rain purified by the Sun from the waters of the Pacific Ocean.

More Effective and Stays Effective…

The performance of barriers drop over time. Not so with steam distillation. Not only is steam distillation more effective, it stays that way!

The Pure Water C-630 Steam Distillation System

- Can be wheeled through a standard door for ease of movement prior to installation and can be easily relocated if needed.

- Designed for easy servicing from just the front and right side – This saves space!

- Simple operation. Only 8 moving parts. Designed for operation all over the world.

- Virtually no noise.

- No expensive high speed components to wear out.

- Very simply maintenance program.

- Constant purity monitoring.

- Automatic start-up and shut down.

- Energy-efficient system.

- Stainless Steel Throughout.

How it Works…

This patent pending system is a marvel of engineering ingenuity. Carefully designed to work on pressure differentials that impact the boiling point in each chamber. The C-630 boils the water in the first chamber from external energy. By carefully controlling the boiling points thereafter, the steam from each chamber is sufficiently superheated to boil the water in the subsequent chambers sequentially. The initial energy is thereby used six times to produce water of outstanding purity, and a remarkably low cost. Couple this with the low maintenance of the system and you can see the benefits for you.

Step by Step

- Raw water enters the boiling chamber where it is boiled to produce steam.

- The steam rises through a separator to remove droplets which might contain impurities.

- Steam enters the heat exchange chamber where it gives up its heat through the walls. This heat is used to boil raw water in the second chamber.

- The condensed steam collects to the bottom of the heat exchanger as high purity distilled water.

- The steam from the raw water in the second boiling chamber goes through the next separator and repeats the process.

- After the initial boiling action, the steam is reused 5 times to boil additional raw water without the use of more energy.

Reviews

There are no reviews yet.